-

Contracted assembly

Our modern machinery and highly advanced production lines allow us to provide comprehensive services of automated assembly of SMD surface mount devices and through hole wave soldering assembly.

Assembly of electronic components

Our modern machinery and highly advanced production lines allow us to provide comprehensive services of automated assembly of SMD surface mount devices and through hole wave soldering assembly. We assure maintaining of stock of materials for production with full records of customer-provided materials, guarantee of safety and proper storage in accordance with the standards that are currently in force.

Design

We offer a full range of engineering services, from preparation of the concept of operation equipment and systems, design, software development and preparation of detailed design documentation. The results of work of our team of designers are products meeting assumptions of the project and optimized in terms of production costs.

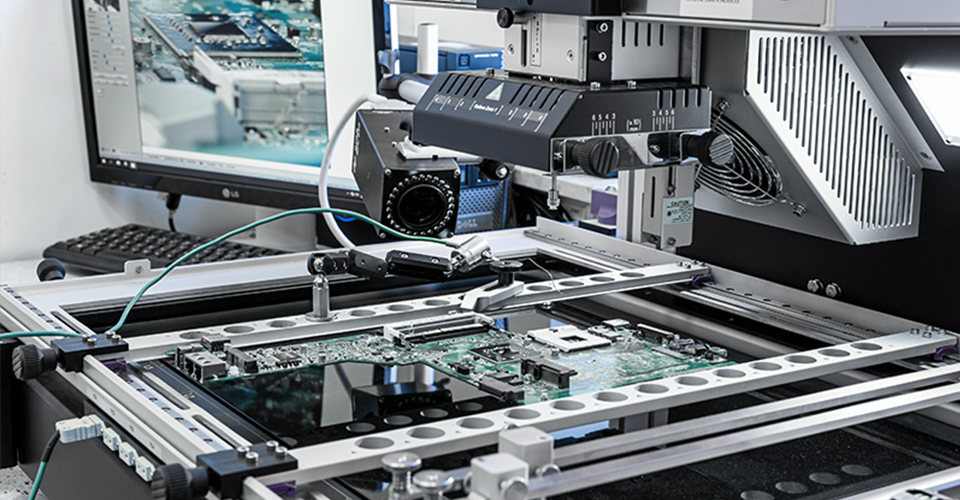

SMT assembly

In the scope of SMT assembly, SiMS offers a wide range of the following services:

- single and double-sided SMD assembly in reflow soldering technology,

- manual assembly of through hole and wave soldering,

- complementary through hole and mechanical component assembly,

- mixed assembly,

- automated optical control of assembled printed circuit boards

Depending on customer requirements and needs, assembly can be performed with the use of our own or customer-provided materials.

Our range of services is expanded by

- PCB design,

- paste and glue template design,

- picking of components for assembly, including securing stock of printed circuit boards and templates for solder paste and glue application according to customer-provided documentation,

- testing of assembled PCBs in accordance with customer’s guidelines

Our line for SMD assembly

JUKI FX-3 (Super High Speed Chipshooter) - ) - assembly machine

FX-3 automated machine is a high performance chip shooter equipped with 4 heads with 6 nozzles each. Machine efficiency measured in accordance with IPC 9850 standard is 60,000 components per hour. The machine is provided with laser centering, which aligns components in-flight between the feeder and the board.

• PCB dimensions, min 50x50mm, max 410x360 mm

• max height of components at the BOTTOM 40 mm

• 4 heads, each one picks up simultaneously 6 components (a total of 24 components can be picked up at the same time)

• efficiency 60,000 components per hour

• size of components between 0201 (0.4x0.2 mm) and 33.5x33.5 mm

• precision +/- 50 um

• maximum number of feeders 8mm - 120 pieces

• maximum number of feeders 8mm - 120 pieces

JUKI KE-2060R

Assembly line for SMD components with efficiency of 12,500 components/hour. The line is based on JUKI KE-2060R machine, utilizing laser and visual alignment. In this way, we are able to align components sized between 0.6x0.3mm (0201) and 150x50 mm with precision up to +/- 0.05mm with laser alignment and +/- 0.03mm with visual alignment. Minimum lead pitch of assembled components is 0.2mm and the minimum ball pitch for BGA is 0.25mm. The maximum size of the assembled board is 510x360mm.

HOTFLOW 2/12

We also have the reflow soldering oven - HOTFLOW 2/12. It is latest generation equipment, designed for the needs of lead free soldering. The long heating zone (3,500mm), with controlled temperature profile, allows for soldering of integrated circuits with ultra-fine pitch, including µBGA.

Ekra X4

It is an advanced automatic screen printer. It is provided with an automatic optical PCB centering system and a side board feeder, with a possibility of programming the speed and pressure of squeegees. The machine has the function of vertical separation of the template from the board, which allows to keep up with the high requirements regarding overprint precision: reliability and repeatability, particularly in the case of small pitches. The machine is controlled by a PC, and it can be operated exclusively by a trained operator.

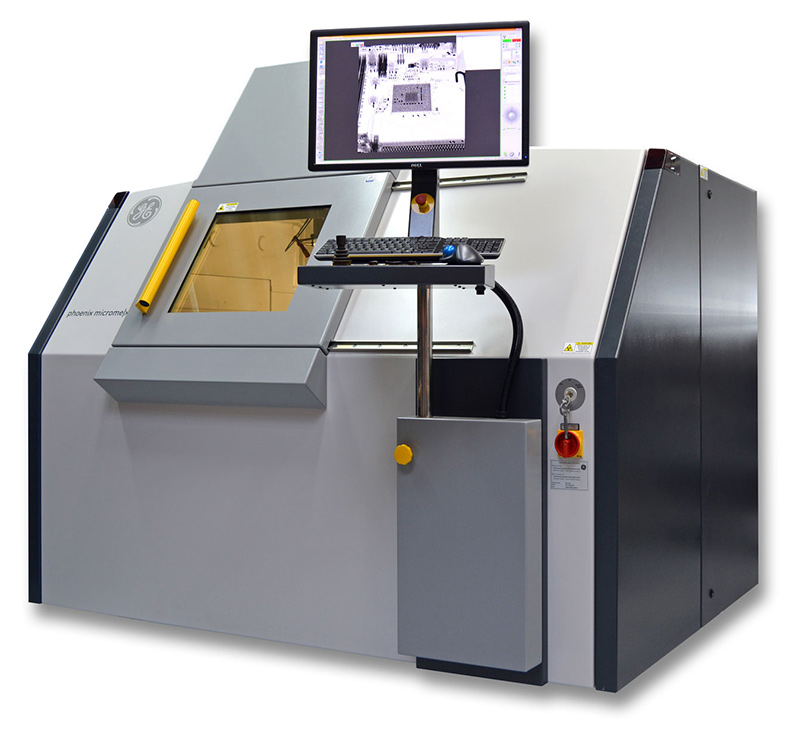

PHOENIX X-RAY PCBA Inspector 130

Semi-automatic, high resolution system dedicated to X-ray inspection of printed circuit boards, consisting of closed X-ray tube, image analysis software and CNC manipulation. It is equipped with the following modules:

1. BGA module – inspection of BGA connections.

• shape

• shifting

• size

• cross fault

• defects

• missing balls

• surplus balls

2. VC module – allows for inspection of electronic subassemblies, semiconductor structures, solder joints in terms of gaps.

• percentage of gaps

• number of gaps

• gap diameter

3. ML module – multilayer PCBs measurement.

4. WIRE SWEEP module – calculation of connecting wire bending or deflection in wire bonding technology.

• voltage 130kV

• power 39W

• max scanning area 610x510 mm2

• max object size 710x560 mm2

• max object weight 5 kg.

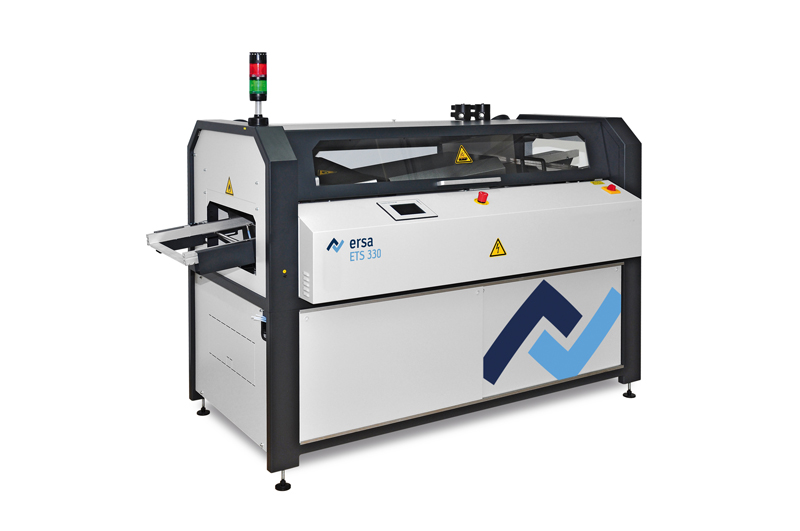

ERSA N-WAVE 330 - wave soldering system

M60

Assembly machine is used for applying SMD components to printed circuit boards and ceramic substrates of hybrid circuits. The machine can be distinguished by its fully visual component centering system, compact mechanical design and reliable control system.